Welsh

Grumpy Mutt

I get a few requests for servicing info, so I will start with a few recomendations, this one will be on the tools you need/ recommended to have before you start. I will populate this post as I go along so that the reader does not have to read a whole thread. 8) IT WILL BE EARLY 1150 BASED, if you have torx where I have Allens, toughies :snorting: :snorting:

If you want tools for a task populated tell me and I will do so.

Detailed info, choice of alternative parts.... go here.... https://wilddog.net.za/forum/index.php?topic=103007.0

1. Engine oil change.

Remove bash plate from engine :sip:

With engine at operating temperature remove drain plug its an 8mm Allen on the bottom of the Engine go find it....

The Filter is on the front left of the motor recessed away, the tool is a 76mm 14 flute most car part shops should have fairly cheap..., if it doesnt grip put a strip of sandpaper in it and tap it on and try again... 8)

Filter part choices see above......

The engine takes 3,5 litres of oil without a filter change, 3.75 litres with a filter change, I do oil at 5,000 km filter at 10,000 km.

The drain uses an 18mm x 22mm crush washer and torqued to 32 Nm

When removing the oil filter check the rubber seal came with or the new one will not fit : when fittin oil the seal and torque to 11Nm or finger tight plus 1/4 turn ish.....

when fittin oil the seal and torque to 11Nm or finger tight plus 1/4 turn ish.....

If you dont know where the filler is you shouldnt be doing this... :sip:

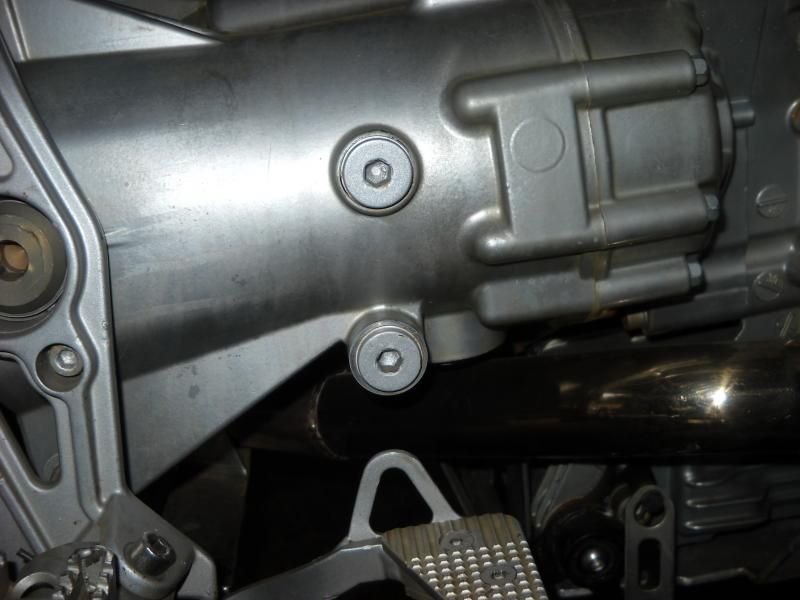

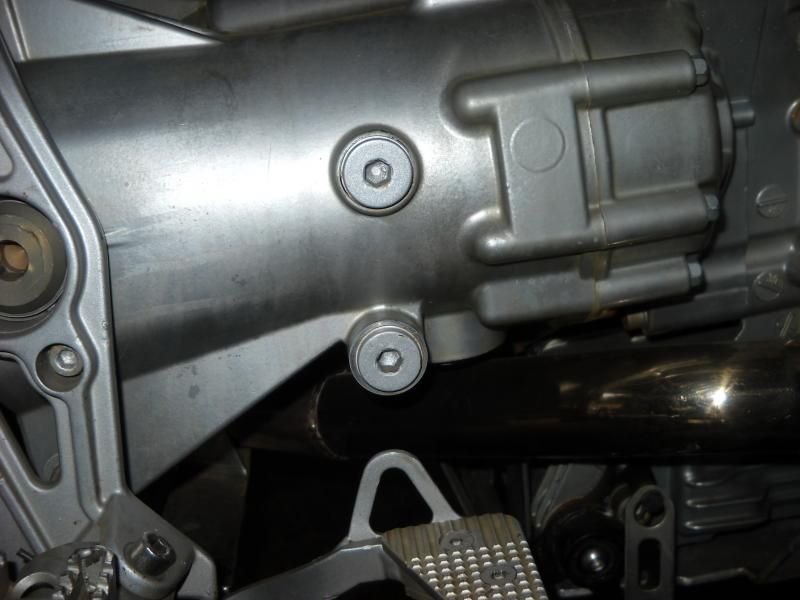

2. Gearbox oil change.

Tools, both plugs on RHS of the box are an 8mm Allen head, these are the normal drain / filling points.

There is a Magnetic plug 14mm Allen head on the bottom of the box RHS, as well, remove if you have "metal" in the box and clean.

Crush washers you need two aluminium 22mm x 18mm

Torque wrench, a 10 - 60 Nm is spot on, you need 30 Nm on the 8mm Allens, no figure for the big 14mm and it doesnt get a crush washer.

Box takes 1 litre of GLi 5 SAE 90 (I use a 75-140 but it must be GLi 5) it is full at the bottom of the filling plug hole.

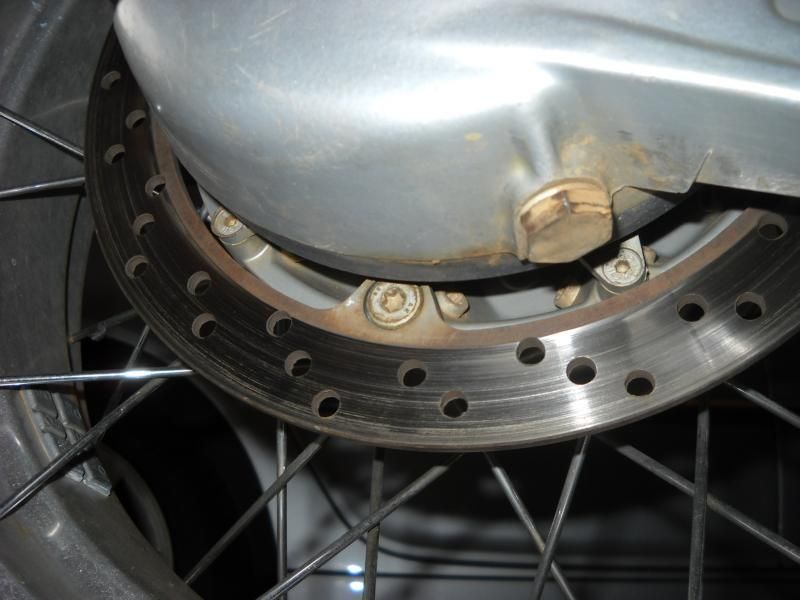

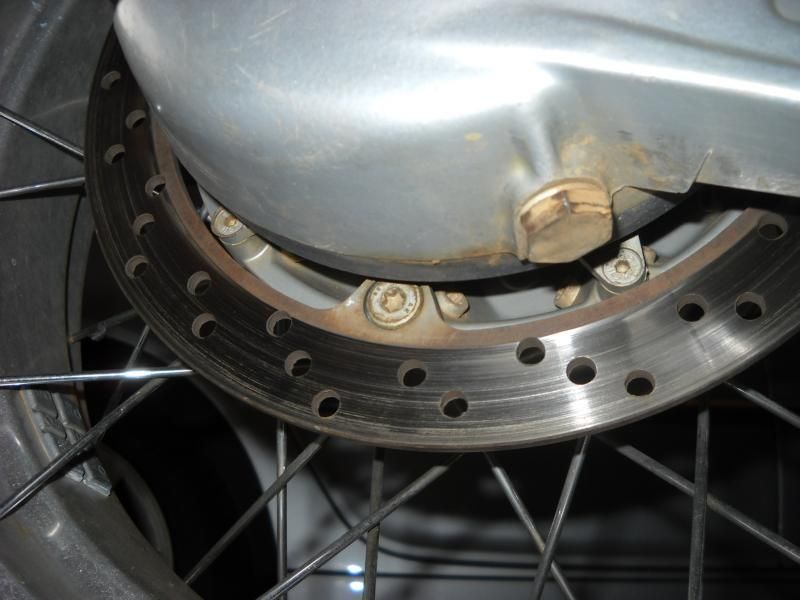

3. Final drive oil change.

The drain is on the bottom...suprise... and is a 19mm hex head.

The filler is a 6mm allen on the top...

Both are torqued to 23Nm so your 10 - 60 Nm torque wrench is spot on again

The crush washers you need two 14mm x 18mm 8)

It only takes about 250ml of oil, fill to bottom of the filler thread 8)

Oil GLi 5 SAE 90 I use a 75-140 but it must be GLi5 8)

4. Final drive pivot adjustment / bearing change.

5. Final drive big bearing / seal change.

6. Swing arm pivot adjustment.

7. Fork seal change.

8. Starter motor removal.

9. Rocker/valve clearance setting.

10. Rocker/valve end float setting.

11. Throttle balance.

12. Clutch fluid change

This is one that gets forgotten, this is where the "dingus" sits on the RHS by the helmet lock, if you have ever wonderred what it is...

Mine is modified... normal bleed nipple, yours may have the original "quck fill" for dealers / production use..

Left OEM right ordinary M10 x 1mm bleed nipple

A couple of 13mm spanners, remove the OEM and with an 11mm fit the new nipple...

Open the master cylinder cover, and top up the fluid.. the lid says what to use.... :biggrin:

I use a cheap impact driver just a light tap but it saves the screw heads or take a good screwdriver and tap the heads....

Bleeding is easier if two of you, put a piece of clear plastic pipe onto the nipple, put the end into a cup with a little brake fluid...

Pressurise the clutch by pulling the clutch lever, open the nipple, close the nipple, pressurise open, close etc etc until you have nice clean fluid and no bubbles... coming out.... 8)

If you want tools for a task populated tell me and I will do so.

Detailed info, choice of alternative parts.... go here.... https://wilddog.net.za/forum/index.php?topic=103007.0

1. Engine oil change.

Remove bash plate from engine :sip:

With engine at operating temperature remove drain plug its an 8mm Allen on the bottom of the Engine go find it....

The Filter is on the front left of the motor recessed away, the tool is a 76mm 14 flute most car part shops should have fairly cheap..., if it doesnt grip put a strip of sandpaper in it and tap it on and try again... 8)

Filter part choices see above......

The engine takes 3,5 litres of oil without a filter change, 3.75 litres with a filter change, I do oil at 5,000 km filter at 10,000 km.

The drain uses an 18mm x 22mm crush washer and torqued to 32 Nm

When removing the oil filter check the rubber seal came with or the new one will not fit :

If you dont know where the filler is you shouldnt be doing this... :sip:

2. Gearbox oil change.

Tools, both plugs on RHS of the box are an 8mm Allen head, these are the normal drain / filling points.

There is a Magnetic plug 14mm Allen head on the bottom of the box RHS, as well, remove if you have "metal" in the box and clean.

Crush washers you need two aluminium 22mm x 18mm

Torque wrench, a 10 - 60 Nm is spot on, you need 30 Nm on the 8mm Allens, no figure for the big 14mm and it doesnt get a crush washer.

Box takes 1 litre of GLi 5 SAE 90 (I use a 75-140 but it must be GLi 5) it is full at the bottom of the filling plug hole.

3. Final drive oil change.

The drain is on the bottom...suprise... and is a 19mm hex head.

The filler is a 6mm allen on the top...

Both are torqued to 23Nm so your 10 - 60 Nm torque wrench is spot on again

The crush washers you need two 14mm x 18mm 8)

It only takes about 250ml of oil, fill to bottom of the filler thread 8)

Oil GLi 5 SAE 90 I use a 75-140 but it must be GLi5 8)

4. Final drive pivot adjustment / bearing change.

5. Final drive big bearing / seal change.

6. Swing arm pivot adjustment.

7. Fork seal change.

8. Starter motor removal.

9. Rocker/valve clearance setting.

10. Rocker/valve end float setting.

11. Throttle balance.

12. Clutch fluid change

This is one that gets forgotten, this is where the "dingus" sits on the RHS by the helmet lock, if you have ever wonderred what it is...

Mine is modified... normal bleed nipple, yours may have the original "quck fill" for dealers / production use..

Left OEM right ordinary M10 x 1mm bleed nipple

A couple of 13mm spanners, remove the OEM and with an 11mm fit the new nipple...

Open the master cylinder cover, and top up the fluid.. the lid says what to use.... :biggrin:

I use a cheap impact driver just a light tap but it saves the screw heads or take a good screwdriver and tap the heads....

Bleeding is easier if two of you, put a piece of clear plastic pipe onto the nipple, put the end into a cup with a little brake fluid...

Pressurise the clutch by pulling the clutch lever, open the nipple, close the nipple, pressurise open, close etc etc until you have nice clean fluid and no bubbles... coming out.... 8)