- Joined

- Oct 2, 2007

- Messages

- 1,758

- Reaction score

- 920

- Bike

- Triumph 800 XC

Following a comment I made on another thread, I thought there may be interest in an Oil Cooler thread for the bike.

I've been reading thru the www.xl500.de and www.alttec-classics websites in Germany and there is a lot of good info there.

Unfortunately not all of you can speak German, so I've made an abridged version of the most important bits.

Here goes:-

Oil temperatures in a standard XL/XR on a normal day, ambient temperature 25°C can go as high as 140°C.

A typical 10w40 graded oil guarantees the oil film integrity up to 120°C. (As you can see this causes problems for the XL/XR 500's operating at high throttle settings for extended periods of time, especially at "Hot and High" locations like Johannesburg, and South African summer conditions as a whole.

Despite careful maintenance by the owner, failures of the engine due to oil failure is still a problem.

After installation of an oil cooler, oil temp falls to around 115°C. This is a very helpful improvement, setting the oil temperature back inside of its specified operational limits.

This extends the useful lifespan of the oil and as a direct result, the engine.

Here are some ideas..

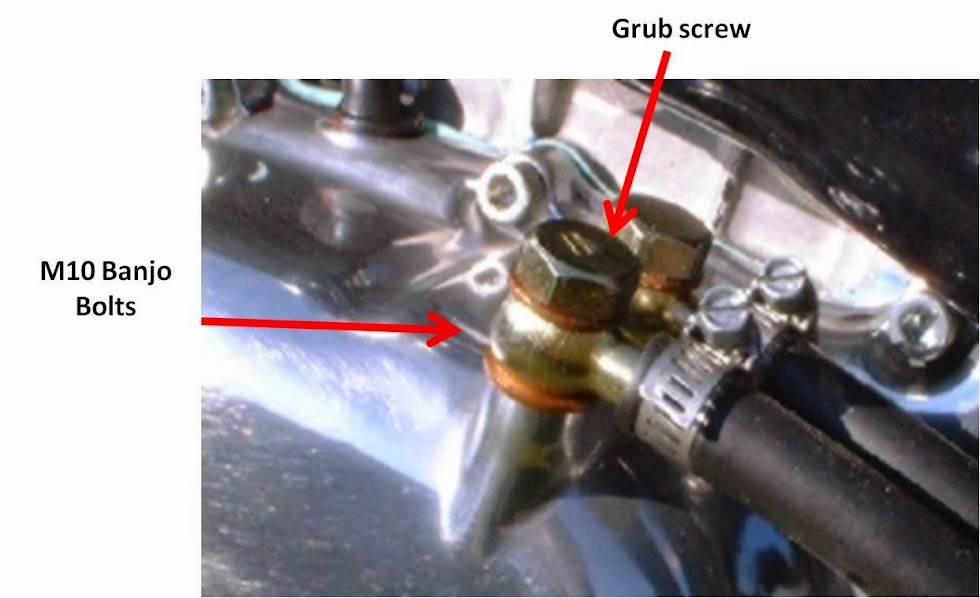

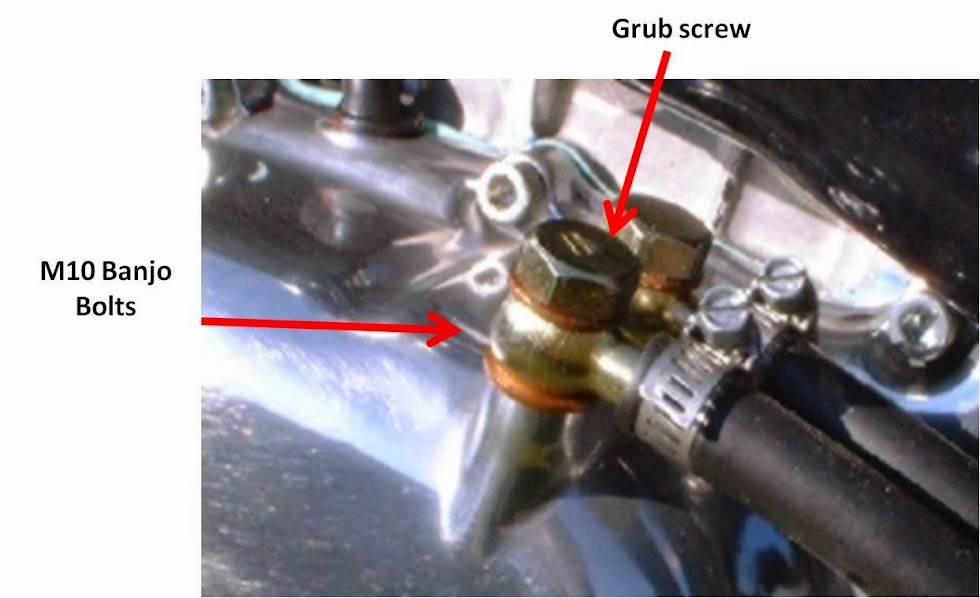

Drilling through the channel on the right hand engine cover. 2 holes drilled and tapped to accept the Banjo Bolts (M10) A grub screw has to be inserted and loctited between the 2 banjo bolts to interrupt the oil flow through the channel. This enables oil to be diverted to the oil cooler.

The oil channel is visible in the cover..

This is the original oil channel running back through the flyweight assembly and then up the barrel to the cylinder head. It is interrupted by fitting a grub screw as described above, diverting the oil path to the cooler, then back again.

The inserts....

Fitted (This is my XR600 but the 500 is the same)

It works great on my 600 and the German boys all claim it does the 500 a world of good.

I've been reading thru the www.xl500.de and www.alttec-classics websites in Germany and there is a lot of good info there.

Unfortunately not all of you can speak German, so I've made an abridged version of the most important bits.

Here goes:-

Oil temperatures in a standard XL/XR on a normal day, ambient temperature 25°C can go as high as 140°C.

A typical 10w40 graded oil guarantees the oil film integrity up to 120°C. (As you can see this causes problems for the XL/XR 500's operating at high throttle settings for extended periods of time, especially at "Hot and High" locations like Johannesburg, and South African summer conditions as a whole.

Despite careful maintenance by the owner, failures of the engine due to oil failure is still a problem.

After installation of an oil cooler, oil temp falls to around 115°C. This is a very helpful improvement, setting the oil temperature back inside of its specified operational limits.

This extends the useful lifespan of the oil and as a direct result, the engine.

Here are some ideas..

Drilling through the channel on the right hand engine cover. 2 holes drilled and tapped to accept the Banjo Bolts (M10) A grub screw has to be inserted and loctited between the 2 banjo bolts to interrupt the oil flow through the channel. This enables oil to be diverted to the oil cooler.

The oil channel is visible in the cover..

This is the original oil channel running back through the flyweight assembly and then up the barrel to the cylinder head. It is interrupted by fitting a grub screw as described above, diverting the oil path to the cooler, then back again.

The inserts....

Fitted (This is my XR600 but the 500 is the same)

It works great on my 600 and the German boys all claim it does the 500 a world of good.