Big Al

Race Dog

Hi guys,

need to bounce this off a few technical minds and get feedback. Soundboard please.

I'm rebuilding a K 75 Brick, everything is pretty stock, except I've gone wire wheels route to add that extra WOW factor.It's certainly looking the part, however, my rear now sits about 10 mm's as close as damn, off center.

The problem is the GS 1100 wheels are thicker than the K's mags. It's really ever so close, I know 10 mm's should do the trick. But, for me to gain 10 mm's, I need to get the wheel machined. I have found a crowd that have large Mills and equipment, and they say yes, with the wheel\tyre all still together, their machine can do the job no problem. Sorted.

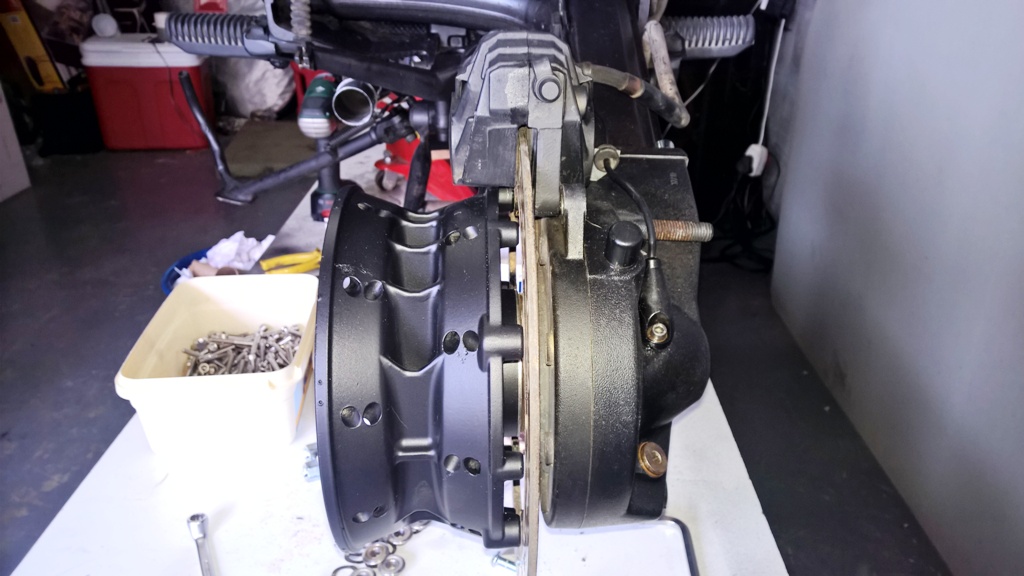

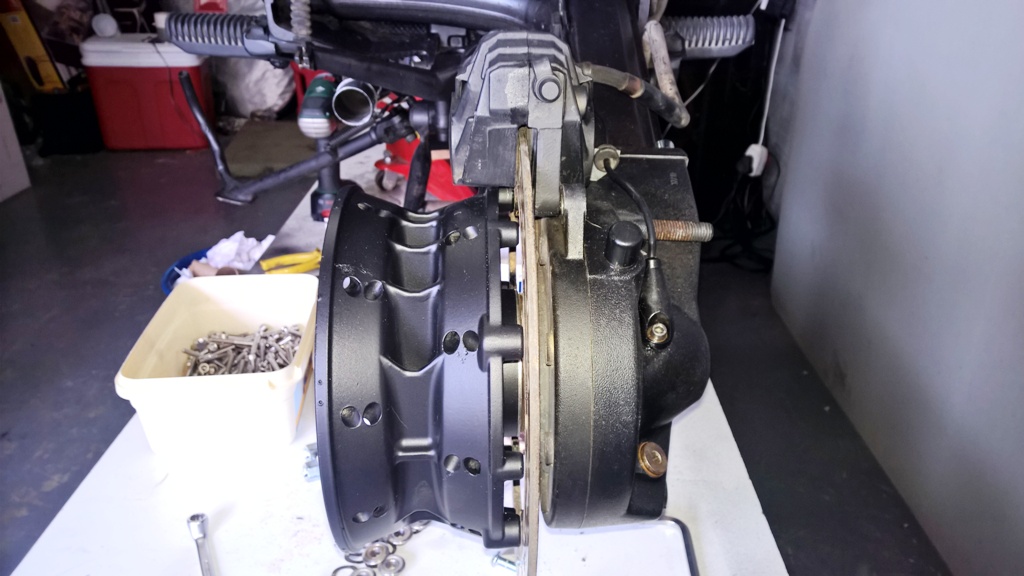

So, here's the Pic.

What is obvious is there isn't 10 mm's clearance between the disc and the inside surface of the Final Drive. So, If I machine off 10 mm's off the mating surface where the hub bolts onto the final drive, do I also take off 10 mm's off the disc mounting points? There is sufficient meat left in the moldings to bolt the disc up, so I guess that's my only real concern. Can anyone tell me why I shouldn't do this, and if they can foresee another problem down the road?

(Oh, PS, the Caliper is also not going to be used), I have ordered a set of calipers off a 2006 GS 1200, which has a thinner profile and should bolt to the swingarm and not foul the spokes (which this one does). But, I'm assuming if I take 10 mms off the disc mounts, the disc by default should stay in the same position it's in now, but the wheel will be 10 mm's close to t\he final drive, and therefore, the center of the tyre will be center of the frame\bike.

Is my logic sound?

thanks in advance guys

regards

Alan

need to bounce this off a few technical minds and get feedback. Soundboard please.

I'm rebuilding a K 75 Brick, everything is pretty stock, except I've gone wire wheels route to add that extra WOW factor.It's certainly looking the part, however, my rear now sits about 10 mm's as close as damn, off center.

The problem is the GS 1100 wheels are thicker than the K's mags. It's really ever so close, I know 10 mm's should do the trick. But, for me to gain 10 mm's, I need to get the wheel machined. I have found a crowd that have large Mills and equipment, and they say yes, with the wheel\tyre all still together, their machine can do the job no problem. Sorted.

So, here's the Pic.

What is obvious is there isn't 10 mm's clearance between the disc and the inside surface of the Final Drive. So, If I machine off 10 mm's off the mating surface where the hub bolts onto the final drive, do I also take off 10 mm's off the disc mounting points? There is sufficient meat left in the moldings to bolt the disc up, so I guess that's my only real concern. Can anyone tell me why I shouldn't do this, and if they can foresee another problem down the road?

(Oh, PS, the Caliper is also not going to be used), I have ordered a set of calipers off a 2006 GS 1200, which has a thinner profile and should bolt to the swingarm and not foul the spokes (which this one does). But, I'm assuming if I take 10 mms off the disc mounts, the disc by default should stay in the same position it's in now, but the wheel will be 10 mm's close to t\he final drive, and therefore, the center of the tyre will be center of the frame\bike.

Is my logic sound?

thanks in advance guys

regards

Alan